EN Inspections

Safe working starts with reliable protection. We specialize in inspecting, testing, and managing personal protective equipment (PPE) and work equipment. With extensive experience, we help companies in construction, industry, logistics, and technology comply with laws and regulations – and prevent accidents.

We inspect a wide range of work equipment and PPE – from ladders and fall protection to lifting equipment and stairs. Whether it’s an annual inspection or a safety check, at CIJ Borculo you are assured of expertise, independence, and efficiency.

Questions? Feel free to contact our account manager:

Bennie Luttikholt

+31 (0)6 – 25643875

b.luttikholt@cijborculo.nl

What is personal protective equipment?

Personal protective equipment (PPE) includes all devices and tools that protect employees from hazards in the workplace. Besides clothing and helmets, it also covers equipment that provides protection when working at height, lifting, or hoisting.

Examples of equipment we inspect and test:

Ladders and stairs: Portable climbing equipment for access at height.

Fall protection: Harnesses, lifelines, anchor points, and fall arrest devices.

Lifting equipment: Slings, chains, lifting eyes, hooks, and shackles.

Hoisting equipment: Hoists, jacks, lifting columns, and other lifting aids.

An important part of PPE is fall protection – more about that below.

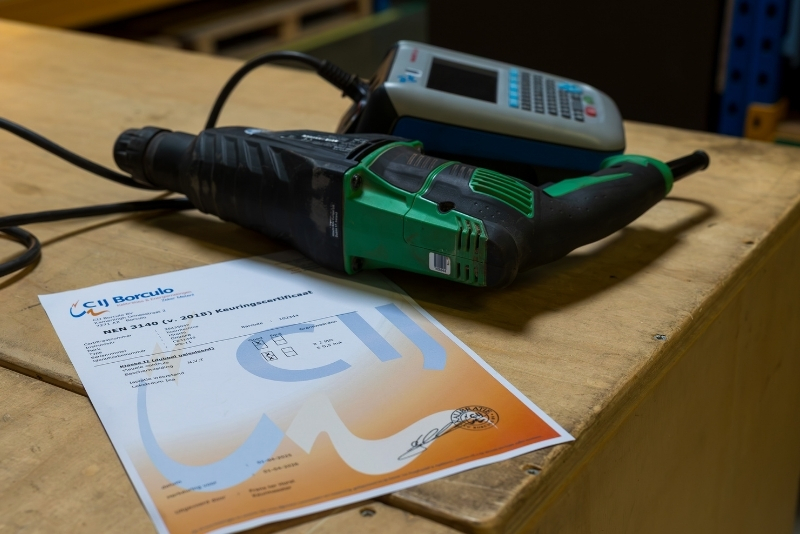

NEN 3140

In addition to personal protective equipment, we also inspect all work equipment used daily in offices according to NEN 3140, ensuring that office employees can work in a safe and healthy environment. Examples include:

Chargers and docking stations

Power strips and cables

Electrical tools

NEN 2484

NEN 2484 sets the requirements for portable climbing equipment such as ladders, steps, and folding ladders. Whether you are a painter, technician, or installer – safe climbing starts with certified equipment. CIJ Borculo inspects:

Steps

Ladders

Climbing equipment

Fall protection according to NEN standards

Fall protection includes all equipment designed to protect people from falls. In practice, a distinction is often made between horizontal fall protection (e.g., on flat roofs) and vertical fall protection (e.g., in transmission towers or wind turbines).

The NEN standards use a different categorization, with one overarching standard (NEN 365) and sub-standards that apply to specific types of fall protection:

Harnesses (NEN 361): Absorb fall forces and keep the user upright.

Retractable fall arresters (NEN 360): Automatic fall stoppers that lock when a fall occurs.

Guided fall arresters (NEN 353): Anchored to a vertical line, moving with the user.

Lanyards and energy absorbers (NEN 354/355): Lifelines for fall arrest.

Work positioning systems (NEN 358): Allow employees to work at height with both hands free.

Anchorage devices (NEN 795): The point where fall protection is secured.

Descender devices (NEN 341): For descending into confined spaces such as shafts.

In practice, NEN 360, NEN 361, and NEN 365 are the most important for most companies, as this equipment is the most widely used.

Benefits of EN Inspections

Safety: Prevents accidents, injuries, and material damage.

Legal compliance: Mandatory inspections under Dutch Occupational Health and Safety legislation.

Insurance coverage: Essential for liability in the event of an accident.

Insight into equipment condition: Prevents surprises and unplanned downtime.